Choose

PROCESSES

TECHNIC

Maximum quality assurance through Non-destructive and destructive testing methods

On the one hand, we use non-destructive testing to weed out components with defects. On the other hand, we thus ensure the quality of all components in operation.

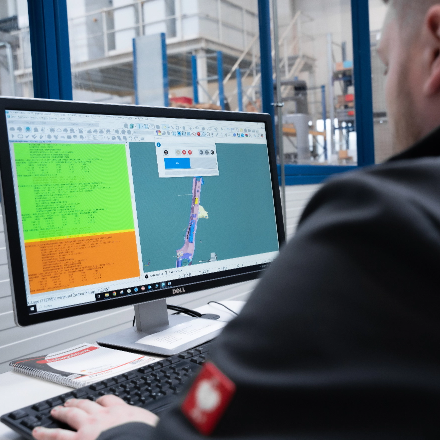

In ongoing series production, the quality of the components is ensured by means of monitoring, including robot-assisted measurements with 3D laser scanning. The Perceptron automated metrology solution makes it possible to maintain, correct, check and control the manufacturing quality immediately and at any time, at full production speed and without touching the component.

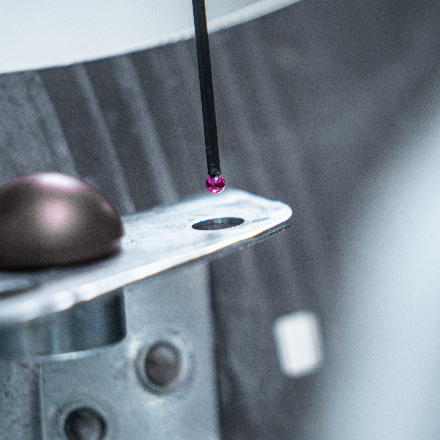

We also use ultrasonic testing and SmartRay for weld monitoring and various Hexagon measuring machines to measure components and eliminate deviations.

For destructive testing, we work with out-of-specification testing, cutting, press-out force testing, and examination of ground samples using a microscope.

- Inline measurement technology Perceptron for robot-assisted measurements with 3D laser scanning

- SmartRay for weld seam monitoring by non-contact visual 3D inspection

- Ultrasound to determine the location as well as the size of the defect in the component

- Other destructive methods for inspection by microscope

Technical features

Ultra sonic

Lamination tests, wall thickness measurements and weld seam tests in the industrial sector

Perceptron

SmartRay

100% inline inspection,

3D laser scanning

DEA Measuring machine

Table size max. 1.200 x 850 mm

Microscope

Material / Flexibility

Ultra sonic

Metals, castings, plastics, rubber, ceramics and composites

Perceptron

no restrictions

SmartRay

no restrictions

Microscope

no restrictions

References