Choose

PROCESSES

TECHNIC

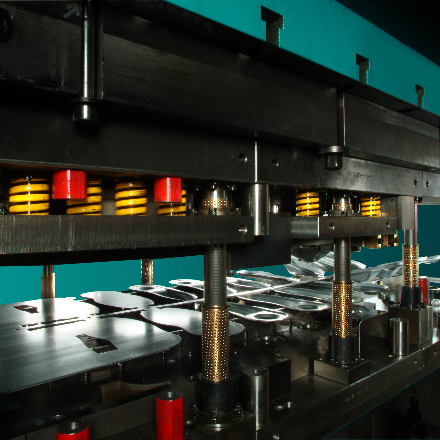

Effective forming with impressive force

Our forming production is based on precise simulation processes and the many years of expertise of our specialists. Thanks to state-of-the-art production equipment, including mechanical, hydraulic and fluid cell presses, we are able to efficiently form a wide range of metals.

We use various technologies in our forming processes, such as progressive or transfer forming and conventional deep drawing. In addition, we are also proficient in hydromechanical forming and hydroforming (IHU).

- Precise forming simulation for efficient forming

- Various process technologies

- Extensive press park

- In-house toolmaking and maintenance

Technical features

4 Hydraulic presses

200 – 630 t forming pressure (max. 1,730 mm x 2,500 mm)

4 Mechanical presses

450 – 2,000 t forming pressure (max. 5,100 mm x 2,200 mm)

1 Fluidcell press

up to 1,400 bar (max. 1,600 x 3,000 mm)

Material / Flexibility

Steel

High-strength, high-strength and high-alloy steels

Aluminium alloys

no restrictions

Magnesium alloys

no restrictions

Nickel-based alloys

no restrictions

Copper

no restrictions

References