Choose

PROCESSES

TECHNIC

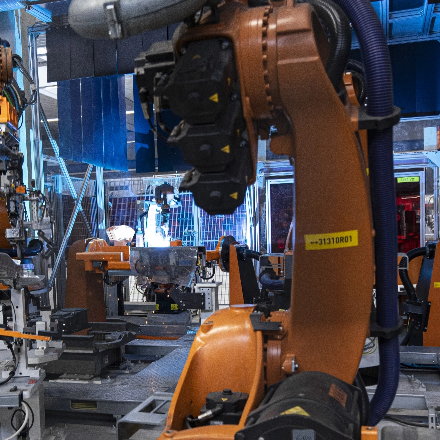

Welding made to measure Precise connections for every challenge

Our welding processes meet the industry standard and satisfy a wide range of requirements.

Our experts use a variety of welding processes – from the standard arc processes (MAG, MIG, TIG) to laser welding. State-of-the-art production facilities with various 5-axis guide machines are used. We are particularly specialized in the low-distortion laser welding of high-quality seams on difficult-to-weld materials. Using specially developed laser heads, we can even reach and process inaccessible areas of components.

- Clinching, gluing or riveting as further joining variants possible

- Laser welding systems for large series components

- Special areas such as resistance welding (spot welding) or CMT (Cold Metal Transfer)

- 5-axis systems and laser beam sources with max. power of 6 kW

Technical features

3 Laser welding systems

2.5 – 6 kW,

Working range from max. 2,000 – 4,000 mm

150 Robots

for series production,

can be adapted individually

WIG

Workstation with manual welder for tightest tolerances

MAG

Workstation with manual welder for tightest tolerances

Gluing

Project related application

Clinching

Project related application

Material / Flexibility

Steel

unalloyed and high-alloyed

from 0.5 to 6 mm automated,

from 0.1 to 10 mm manual

Aluminium materials

from 0.5 to 6 mm automated,

from 0.1 to 10 mm manual

Titan

from 0.5 to 6 mm automated,

from 0.1 to 10 mm manual

Nickel based materials

from 0.5 to 6 mm automated,

from 0.1 to 10 mm manual

References